Organisation and Services

- Experienced production teams operating in a 3-shift structure (24h/5 days).

- Clear described responsibilities and tasks, ran by our Team Leaders.

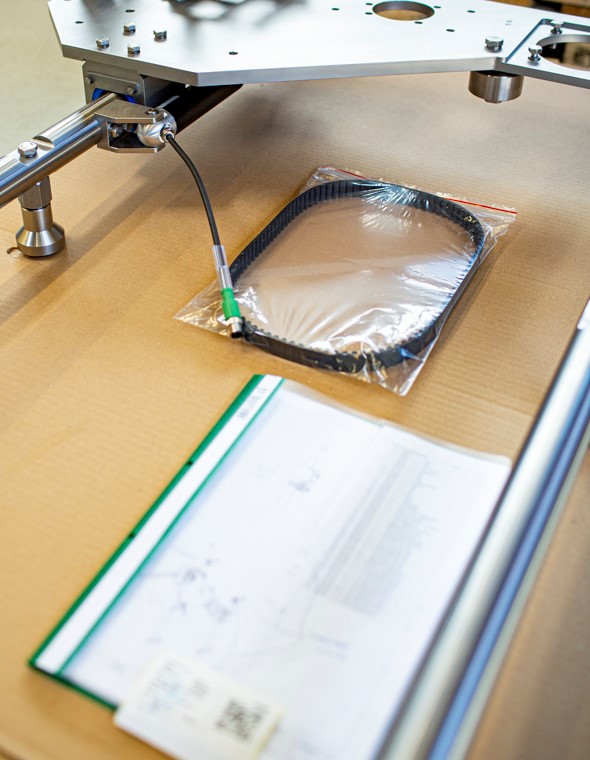

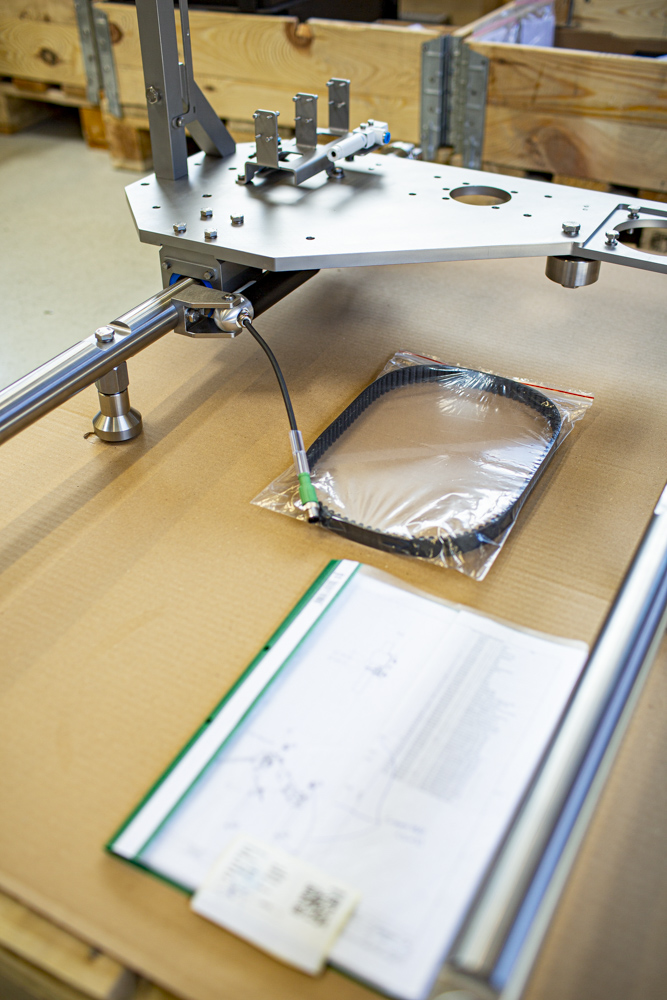

- For each order a production file is made.

- Very strict quality checks like 1st and statistical parts inspection, for each process step.

- Modern CNC machines, all new bought, controlled maintenance, all equipped with Oil-mist filters providing clean and healthy work environment.

- This department also provide following services:

- Glass-Pearl blasting (only for Stainless Steels and Aluminium’s)

- Straitening/adjusting

- Certain surface polishing’s

Organisation and Services

- Experienced production teams operating in a 3-shift structure (24h/5 days).

- Clear described responsibilities and tasks, ran by our Team Leaders.

- For each order a production file is made.

- Very strict quality checks like 1st and statistical parts inspection, for each process step.

- Modern CNC machines, all new bought, controlled maintenance, all equipped with Oil-mist filters providing clean and healthy work environment.

- This department also provide following services:

- Glass-Pearl blasting (only for Stainless Steels and Aluminium’s)

- Straitening/adjusting

- Certain surface polishing’s

Order based

Here it starts with RFQ’s and fast response with Price offers, PO’s and again fast response with PO confirmations. Our Sales team works fast, very fast. You know where you stand, clear communication and we only promise what we know for sure we can do. Our OTD goal is 95%.

Production preparation

Each new or revised part is reviewed and prepared by our Engineer Department. All CNC programs are made with use of CAD/CAM. CAM simulations are used to avoid problems in the real production process. A complete Production instruction is made for the CNC operators resulting in a high machine ON-time.

Tooling

CNC operators are supported by a separate Tool section with Tool Setters preparing the tools. Tool data together with CNC programs are transferred straight from the central system into the planned CNC machine.

Order based

Here it starts with RFQ’s and fast response with Price offers, PO’s and again fast response with PO confirmations. Our Sales team works fast, very fast. You know where you stand, clear communication and we only promise what we know for sure we can do. Our OTD goal is 95%.

Production preparation

Each new or revised part is reviewed and prepared by our Engineer Department. All CNC programs are made with use of CAD/CAM. CAM simulations are used to avoid problems in the real production process. A complete Production instruction is made for the CNC operators resulting in a high machine ON-time.

Tooling

CNC operators are supported by a separate Tool section with Tool Setters preparing the tools. Tool data together with CNC programs are transferred straight from the central system into the planned CNC machine.

Quality Assurance and Control

Only high Quality materials are purchased from reliable international suppliers. If not available in Romania, we purchase and import materials ourselves within Europe (mainly Germany and The Netherlands). All materials are subject to Incoming Goods Inspection.

For each client order line we make a QA/QC plan based on the drawing specifications and Client instructions. Production is first checked by the production operators and then by the QA inspector. For each production step one or more QA inspections are required depending on the QC plan. All data is recorded.

The Quality Department inspectors check according to the Inspection Plan made for each Order item all dimensions and requirements as per subject drawing and client applicable specifications. We believe thoroughly testing saves additional work/materials and delays. Therefore we test each production step and repeat checking critical dimensions after outsourced operations like (surface) treatments.

Quality Assurance and Control

Only high Quality materials are purchased from reliable international suppliers. If not available in Romania, we purchase and import materials ourselves within Europe (mainly Germany and The Netherlands). All materials are subject to Incoming Goods Inspection.

For each client order line we make a QA/QC plan based on the drawing specifications and Client instructions. Production is first checked by the production operators and then by the QA inspector. For each production step one or more QA inspections are required depending on the QC plan. All data is recorded.

The Quality Department inspectors check according to the Inspection Plan made for each Order item all dimensions and requirements as per subject drawing and client applicable specifications. We believe thoroughly testing saves additional work/materials and delays. Therefore we test each production step and repeat checking critical dimensions after outsourced operations like (surface) treatments.

Measuring systems

Emtech is using latest technologies in measuring systems. Our Quality department is provided with:

- A programable large CMM

- TESA Height meters

- Digital Micrometres

- Digital callipersGo/No-Go gauges etc.

All are frequently calibrated by an external specialist measuring institute.

Quality Assurance and Control

Only high Quality materials are purchased from reliable international suppliers. If not available in Romania, we purchase and import materials ourselves within Europe (mainly Germany and The Netherlands). All materials are subject to Incoming Goods Inspection.

For each client order line we make a QA/QC plan based on the drawing specifications and Client instructions. Production is first checked by the production operators and then by the QA inspector. For each production step one or more QA inspections are required depending on the QC plan. All data is recorded.

The Quality Department inspectors check according to the Inspection Plan made for each Order item all dimensions and requirements as per subject drawing and client applicable specifications. We believe thoroughly testing saves additional work/materials and delays. Therefore we test each production step and repeat checking critical dimensions after outsourced operations like (surface) treatments.

Measuring systems

Emtech is using latest technologies in measuring systems. Our Quality department is provided with:

- A programable large CMM

- TESA Height meters

- Digital Micrometres

- Digital callipersGo/No-Go gauges etc.

All are frequently calibrated by an external specialist measuring institute.

Measuring systems

Emtech is using latest technologies in measuring systems. Our Quality department is provided with:

- A programable large CMM

- TESA Height meters

- Digital Micrometres

- Digital callipersGo/No-Go gauges etc.

All are frequently calibrated by an external specialist measuring institute.